TON

Czech Tradition and Craft TON

Honest bentwood furniture

The company TON, based in Bystřice pod Hostýnem, is based on a more than 150-year-old tradition. The hand-bent furniture is created in the place where the only Thonet factory that developed and used this unique technology started its operation in 1861. Even in its day, the factory was one of the largest of its kind and, thanks to its location amongst extensive beech forests, it was right at the source of quality material with the best bending properties, saving not only on transport costs but also on labour. In 1953, the Thonet factory was renamed TON - Factoryfor Bent Furniture. Since 1994, the company has introduced a number of successful models to the Czech and foreign markets, e.g. the Merano armchair won a number of international design awards, but the greatest success was the SPLIT collection (awarded the Red Dot title), which was the first in the world to use the technology of splitting solid wood, hand-bent in opposite directions.

TON brand history

Ton began operations in 1861 in Bystřice pod Hostýnem, where it specialised in bentwood furniture, which today is the oldest of its kind in the world. The founder of the company was Michael Thonet. Bystřice pod Hostýnem is surrounded by beech forests, which offer plenty of material for the production process and by keeping the material close to the factory saves on transport costs. Already ten years after opening, the factory in Bystřice pod Hostýnem was producing 300,000 pieces of bentwood furniture per year and with each passing year the production volume increased. Vocational schools for woodworking were also set up in the area, and Thonet also helped to establish kindergartens, build railways, build workers' houses, and a factory band and casino. The First World War put an end to the company's expansion, which plunged into economic crisis. The situation was so serious that in1924 the name was changed to THONET-MUNDUS when the company merged with the joint-stock company Kohn-Mundus. The name TON was not acquired until 1953.

How are TON chairs made?

1. Wood drying

The warehouse first receives about 300 types of wooden chips, which are sorted according to colour. The wood has to be kept at a certain moisture content, so it is sprayed in the summer months and dried in special chambers in the winter months, making the wood both better quality and more durable.

2. Steaming in the kiln

Beech wood is the best of all woods to bend. The wood is placed in rich steam at a temperature of 100 °C. In the steam, the wood is steamed according to the diameter of the square, the time corresponds to an hour for each centimetre.

3. The bending process

The benders place the logs in the formwork, where they seal it and put a special band on it. This ensures that the structure of the wood is not damaged and remains incredibly strong despite the change in shape. It's a complex process that takes more than a year to learn correctly.

4. Staining

The individual pieces of wood or the whole chair go to the staining room, where they are soaked in special vats. However, this step is not necessary, the chairs can be left in their natural colour or just varnished or oiled.

5. Completion

Ton chairs are assembled by hand, and the products are finished in a variety of finishes - varnished, oiled or upholstered. Traditionally, varnishing is done by hand, while oiling allows the wood texture to stand out. The upholstery is done according to the customer's wishes, who can choose the colour and type of fabric, or add decorative nails to the chair.

6. Testing

Quality is one of TON's priorities, which is why the products are thoroughly inspected at every stage of production and undergo specific tests for strength and durability in accordance with European standards. The requirements for seating furniture - strength, durability and safety - stand up to the highest stress tests.

TON chairs made of natural materials

TON chairs are created with hands, heart and unique technologies. Their originality is confirmed by a number of natural properties, linked to the life cycles of trees, animals and handcrafting. The wood is formed from cambium - the layers of cells between the wood and the bark that form the bark on the outside and the wood on the inside. The natural texture of the wood makes each product an original. The company values natural materials and ensures that they are used sparingly throughout the production process, with the aim of going to the limits of minimal impact on the landscape. The company has received ISO and PEFC certification for its environmentally friendly work .

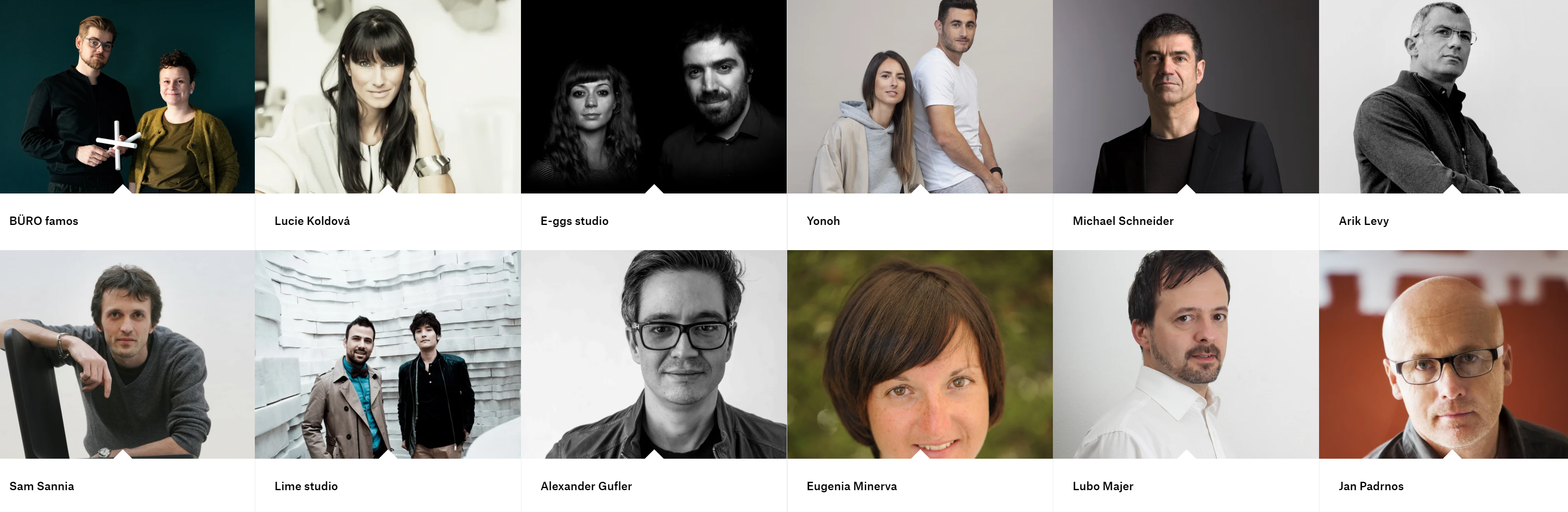

Designers for the TON brand

Dozens of designers from home and abroad work with the traditional Czech brand. It is evident that the fame of Czech skilled hands has spread far and wide and many successful designers want to further develop the TON tradition.

Fly around the world with TON chairs

Far from being a brand known only on home turf, TON's reach extends far into the design world and you'd be surprised wherever you can find pieces from the home-grown TON brand. In addition to dozens of successful projects, either privately or in a contract environment, TON has also worked with globally known brands such as Starbucks, Google and Microsoft.

Where else could the exhibition pieces of Czech design stand out better than in a museum... In the Austrian Gratz Museum you can sit in the Merano armchairs. The amazing wooden interior in the middle photo belongs to the Prague restaurant Our Mill, where the Chips lounge chair has a privileged place. And lastly, the amazing colourful Franz café in Brno with its red lacquered Era 388 chairs.

The site is under construction. If you are looking for or need products belonging to this category, write to us at alax@alax.cz.

We will contact you and then send you an offer.

Thank you for your understanding. Team ALAX